The truss girder welding machine contains Line wire straightening unit, Line wire accumulator, inclined beading bending & moulding structure, Welding system, Truss bridge feeding system, Truss bridge cutting, material receiving system.

Main parameters

| Power supply | 380V, 50Hz | |

| Electric power of welding unit | 800 [KVA] (average 90KVA) | |

| Other machine power | 50 [KW] | |

| Source gas | Row amount | 2000 [l/min at 6 Bar] |

| pressure | 6 [Bar] | |

| Cooling water | Row amount | 150 [l/min] |

| Min. presuure | 3 [Bar] | |

| MAX water temperature | 25 [C] | |

| water inlet | 2 x 1" | |

| water exit | 1 x 3" | |

| Circumstance | temperature | 0 - 40 [C] |

| altitude | < 1000 [m.a.s.l.] | |

| Raw and processed materials | ||

| Yield strength | MAX 600 [N/mm2]s | |

| Tensile strength | MAX 700 [N/mm2] | |

| Elongation | > 14 [%] | |

| Top wire diameter | 6 - 14 [mm] | |

| Bottom wire diameter | 5 - 14 [mm] | |

| Bending wire diameter | 5 -8 [mm] | |

| Truss girder welding machines | ||

| Max welding speed | 15 [m/min] | |

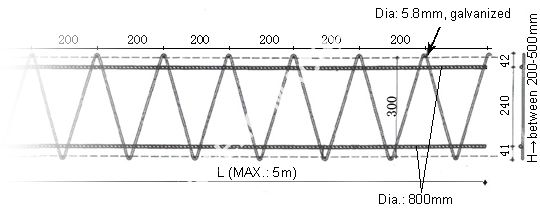

Finished products (2D truss girder)